TM-1080AE Blanking Stripping Machine for Die-cuts

- Comparing to traditional stripping machine which uses gantry frame as the base for installing the stripping mould, our new design adopts one-side independent standing base for installing the stripping mould; this design is space saving, and convenient for operating.

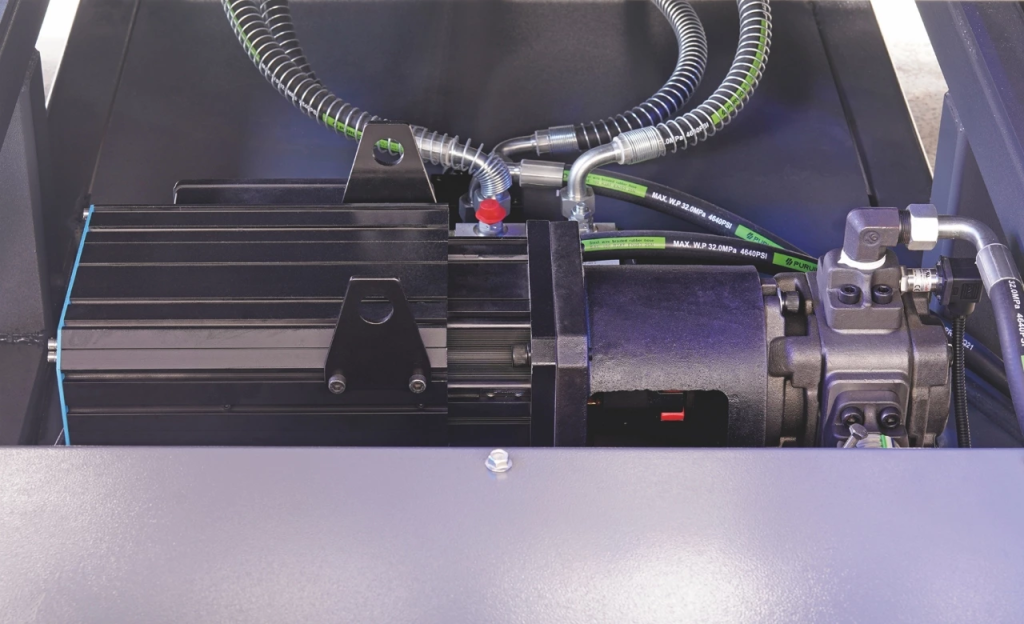

- Hidden type servo motor and ball screw ensures a precise pile positioning.

- Adjustable hydraulic system provides adjustable pressure for processing of different materials of different sizes and weights.

- Stripping needles (rods) are quick and easy to change to fit different products formats and patterns.

- Automatic lubricating system carries out regular lubrication, which greatly extend the service life of the machine.

- The operation panel adopts visual button to avoid safety accident caused by wrong operation. Its also easy and quick to program at the touch screen.

- Safety fence at operation side protects the safety of personnel when the machine is running.