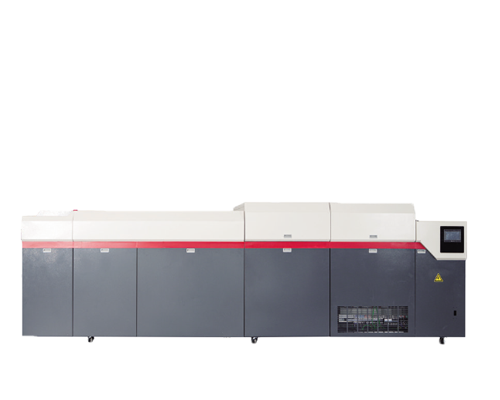

Snowflake Curing Machine ST-1200SF is the newly-developed UV curing equipment especially designed for creating snowflakes effects. It is exclusively used for producing the snowflake effects in cigarette and liquor box packaging. It can be used with the fully-automatic screen printing machines or other equipment. Besides it can also be applied in industries such as screen printing, dyeing, electroplating, and electronic circuit boards for drying, cooling, and other UV special effect curing processes:

The transmission of the snowflake unit adopts flat belts, which ensures that the paper will not have netting when the snowflake ink is ignited. The MK wrinkle lamp is 40w x 4 and divided into 4 independent control groups. The lamp distance can be adjusted. The KF leveling lamp is 2.5KW x 2 and controlled in 2 groups to achieve better leveling of the products.

The UV curing mechanism is composed of special mechanisms and features an ultra-low temperature design. It has its own independent patent for UV curing, which enables the products to reach an angle of less than 55° when cured, preventing the products from deforming and avoiding phenomena such as paper jamming and inaccurate registration.

The snowflake lamp uses 8KW x 1 and is controlled independently. It has an adjustable dimming electronic power supply with a range of10%-100%. Customers can adjust the power of the lamp tube to change the snowflake effect of the products and also the adjustable range of the dimming; It is controlled by a microcomputer touch screen and is equipped with a one-click top cover flip function; It uses photoelectric sensor and pneumatic web belts for automatic deviation correction.

The equipment is configured in a modular way, making it possible to add other functional units in the future. The snowflake lamp can be directly replaced on the side of the equipment during daily use.