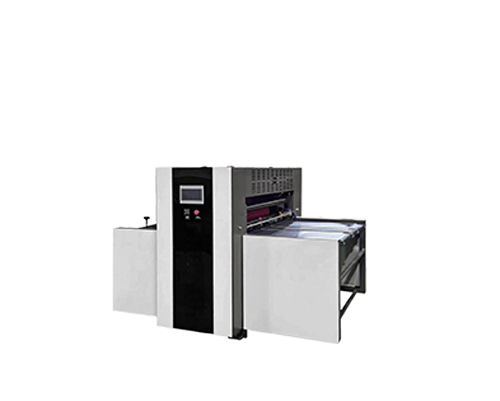

The Semi-automatic Cold Foil Machine ST1100 can be connected with semi-automatic and full-automatic screen printing machine, with snowflake wrinkle detonator, UV curing machine, automatic paper delivery machine to become a collection of wrinkle ink technology, Snowflake Ink Technology, UV glazing, cold ironing and other multi-purpose production line.

Paper Bridge: negative pressure transfer platform, adjustable height up and down, a variety of height can match the front-end equipment. The former device: through the photoelectric and touch screen settings, the tilt of the material can be corrected to flat into the hot stamping mechanism.

High-temperature silicon roller: the oil temperature heating method, low uniform deformation of roller temperature, longer service life. Remote upgrade and trouble shooting: Siemens PLC is used for centralized control, with faster and more stable response. Pressure booster system: equipment pressure booster cylinder, pressure more stable.

Gold Jump Settings: through photoelectric and PLC system settings, paper and paper to complete the jump between the jump and the paper within the jump of the gold position.

Stamping paper with: equipment compatible with 1-inch core, 3-inch core stamping film (available special cold stamping paper and some hot stamping paper) .