- Computerized foil pulling system with 2 pulls to precisely control the foil length as desired.

- 12 zone heating unit with precise temperature controller. Heating zones temperature can be set individually.

- Automatic impression on/off system, with tonnage searching program preset at low tonnage to avoid damaging and reduce the consumption of the paper & foil.

- Steel plate and mold frame can be close and loose automatically, and easy to operate.

- LCD screen master all the function, display unusual spot and location, help fasten the diagnosis.

- Adopts paper catch pincer that can ensure accuracy during high speed operation.

- Lubrication cooler system avoid high oil temperature, protect machine parts wear and tear.

- Operate cutting pressure by computer, digital display accurate and speedy.

- Push and pull 2-in-1 side guide device ease conversion use.

- Feeding and delivery section attached non-stop device. Speedy & automatic conversion.

- Feeding belt buffer structure with accurate performance to the thin paper.

- Hologram system is precision and convenient.

- The stripping unit is facility and fast.

- The Foil rewinding device is easy to handle the waste foil.

- The chain is adopted European brand.

- Imported excellent hardness die cut steel plate. Solid and durable and is hard to be damaged.

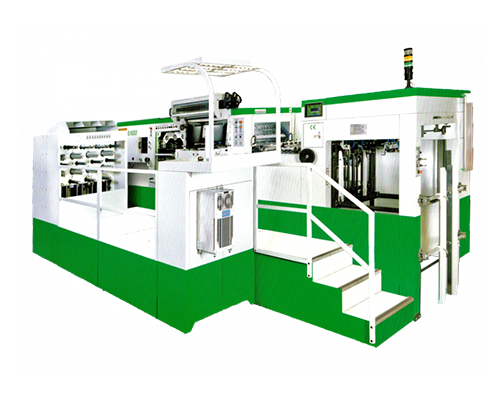

Machinery Dimension – Automatic Foil Stamping With Embossing And Diecutting Platen BD-1050CSF

Computerized foil pulling system with 2 pulls to precisely control the foil length as desired. 12 zone heating unit with precise temperature controller. Heating zones temperature can be set individually.<

Feeder Unit

- Excellent and delicate feeder design that allows stable paper feeding.

- Preparation paper platform to enhance production and performance.

- Non-stop feeding.

- The main platform could move left and right.

Foil Heater Zone Location Map / Hot Foil Control System

- Hot stamping control system.

- To set up the hot stamping fuction.

- Hot stamping heat control system.

- Accurate heating control.

Output Foil Institution

Output foil institution can push to other side of the machine and be convenient to internal operation.

Foil Check/Test Structure

- To check 12pcs of foils are error or not.

- To check if the foil is not in position.

- To see if the foil is broken.

- Adjust the foil displacement anytime.

Touch Screen Monitor System

- Display all information during operation.

- Setting function for die cutting pressure/paper insert length indications etc.

Hologram Foil Stamp System

- Adjustment is convenient.

- Micro adjust on the computer.

- High precise hot stamping.

- You could do three hologram picture together.

Foil Rewinding Device

- Waste foil in roll doesn’t take space.

- No need to use paper core to rewind waste foil.

- Shaft type and easy to take off.

Computerized Foil Pulling System

- Pulling type of foil set Install the foil is convenient.

- High precision deliver foil.

- 2000m foil turntable set.

Heating Plate System

- Hot stamping mould could easily adjust position any time.

- heat-resistant material and not easy deformation.

| Thickness of the gilt paper | 120g/㎡ ~ 2000g/㎡ |

| foil pulling shafts (optional) | 3 shafts (6 shafts) |

| max. foil diameter | 200mm |

| max. rewind diameter | 250mm |

| foil width | 25mm ~ 1020mm |

| maximum.thickness foil plate | 7mm |

| adjustable temperature | 50℃ ~ 180℃ |

| max.hologram stamping area | 1020mm × 730mm |

| paper front fringe & foil membrane gap | 14mm × 23mm |

| heating zone | 12 |

| max.foil stampspeed | 6000 s/h |

| max.hologram stampong speed | 5000 s/h |

| honeycmb | 1 pes |

| foil stamp power required | 24kw |

| rewind shafts (optional) | 6 shafts (12 shafts) |

| Hologram register unit | 3 shafts |

| Stripping unit | 1 unit |

Conveyance Positioning Structure

- Push/Pull device for horizontal positioning.

- Front/back positioning adjustment during operation.

- Double sheet device.

Die-Cutting Station

- Safety die cutting frame design, Easy installation and dismantling. Rotation die frame.

- Design that allows easy replacement of die cutters.

- Imported excellent hardness die cut steel sheet,durable and wear and tear resistance.

| max. paper size | 1050mm × 750mm |

| min. paper size | 400mm × 370mm |

| max. die cutting size | 1040mm × 730mm |

| max. cutting pressure | 300tons |

| min./max. thickness paper | 80g/㎡ ~ 1500g/㎡ |

| max. corrugated board | 4mm |

| min. gripper margin | 8mm |

| max. machine speed | 7500 Sheets/hr |

| inner size of chase | 1145mm × 755mm |

| size of steel plate | 1080mm × 736mm |

| max. feeder overlap height (with platform〉 | 1250mm |

| max. delivery overlap height(with platform) | 1150mm |

| machine total power | 20kw |

| machine length | 7060mm |

| machine width | 2750mm |

| machine height | 5164mm |

| machine weight〈approx.〉 | 18 tons |

Stripping Unit

- Residue removal upper and lower push pin. Easy installation and dismantling. Adjustment is simple and quick.

- Upper structure can be elevated or lowered depending on requirement.